Completed Projects

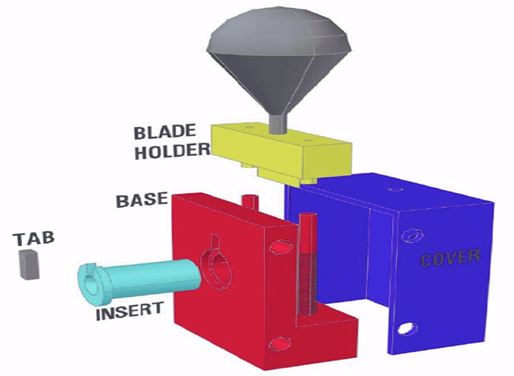

Tube Cutter Improvement (Spring 2014)

The team recently received the tube cutter prototype back from the project partner. The prototype is functional, but the partner requested a new tube cutter that would operate with a slightly larger size tubing and cut this tubing to a specific length. The team is currently re-working the prior design to accommodate these and other changes.

The team has been able to decide on a specific solution for the Tube Cutter this semester. The completed tube cutter was delivered at the end of the Spring 2014 semester and is currently in use at the Wabash Center.

Shim Cart

This project involved creating a better and safer way to transport 'shims' throughout the warehouse. The cart is desgined to handle filled and unfilled rivets, and is even equipped with a brake. The shim cart is currently in use at WCGI.

ADA Room

In this project the team worked on a better way for the individuals with disabilities at WCGI to learn to wash their hands and face, as well as brush their teeth independently. The team delivered a finished protoype last semester.

O-Ring

In this project the team worked on a better way for the staff at WCGI to place O-Rings (small rubber rings that slide on bolts). The task was difficult in itself as the rubber rings are small, and are difficult to fit easily over the bolts as they are. The team delivered a finished protoype last semester.

Paper Folding

This project was completed and delivered. It consisted of designing a more accurate way for folding germination sheets to the correct dimensions. The difficulties with folding these sheets manually included eyeing the correct measurements, creasing the fold, and ensuring that the crease is straight. The team designed a working prototype for WCGI to use.

Cap and Vial

This project was delivered during the Fall 2010 semester right before Thanksgiving Break. It consists of a more useable method for workers to join a plastic cap and vial together.

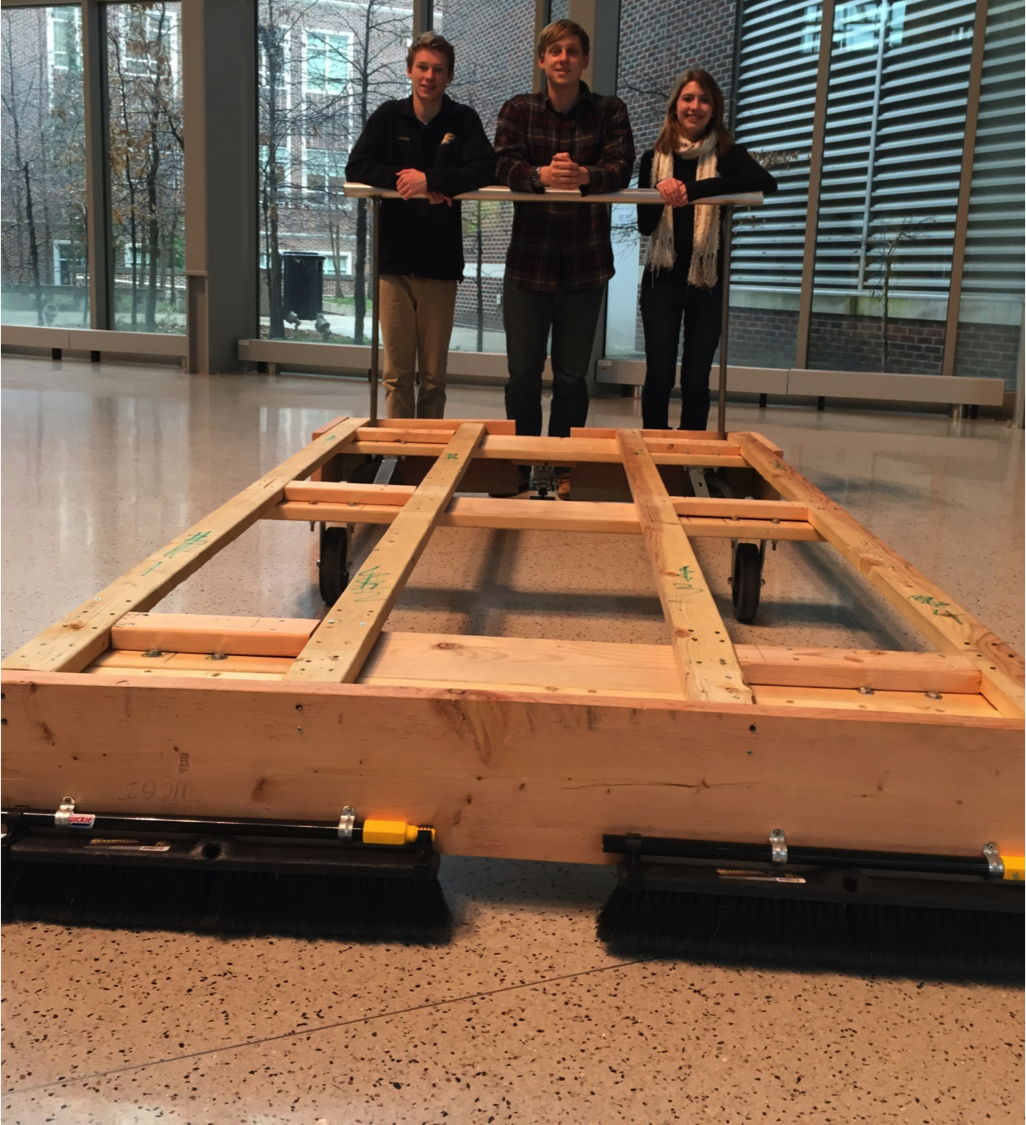

Pallet Transport Team

One of the services at the Wabash Center involves placing rivets in shims for use in semi trailers. The finished shims are placed on a pallet and moved to the loading dock when full. However, moving the skids is cumbersome and inconvenient. Currently, a forklift is used to move the platforms through the working area, causing possible safety concerns for the customers.

The solution to this problem is a large, industrial-strength cart with a wood frame. This semester, our team installed a brake, handle, and made modifications to the frame. By the end of the semester, the Pallet Team wants to deliver the finished cart to the Wabash Center.

Cornhole Team

Customers of the Wabash day Center enjoy many social activities, including outdoor picnics with games such as corn hole. However, some customers are unable to participate due to physical disabilties.

The goal of the Cornhole Team is to allow those with physical handicaps to use a device to play cornhole that allows them to have control. This device will include aiming, distance control, and launching features. This device included aiming, distance control, and launching features. Currently, this project is in the detailed design phase and approaching the delivery phase. The Cornhole Team divided into two teams, which were the Spring Canon Team and the Catapult team. The Spring cannon team made progress during the Spring 2017 semester by installing an automatic winch which pulls the spring and allows for automatic lauch and painting the cannon to make it more attractive.

ADA Toothbrushing Device

Many customers of the Wabash Center learn basic hygiene care and other skills to help them be more independent. However, this routine activity can be made more fun with music!

This team is building on a previous prototype of a previous project that played music for two minutes, the recommended time for brushing teeth. Unfortunately, this popular device failed and is no longer in use. The goal of this team is to determine why the device failed and to create an updated, sturdier product that more closely meets the needs of our project partner.