In Spring 2017 the team was split into two groups completing two separate projects: the Loft Team and the App Team. While the Loft Team projects have been completed and delivered, the App Team project is still ongoing. The App Team is focused on the cataloging of Habitat for Humanity tools, including kiosk creation and database creation. In Fall 2017 another project was added with the Lift System Team. The Lift System Team is tasked with developing a system to transport bycicles and insulation bags up and down floors.

Tools and Materials Management

Lift System

Habitat for Humanity hosts Cover Indiana each year, which is a fundraising event that starts in Lafayette. It features a weeklong 400 mile bicycle tour through Indiana, raising awareness and money for Habitat for Humanity. Our EPICS team has been tasked with finding a better way to store the bicycles that are used in the event.

On August 31, 2017, Sue Hunter led the EPICS HFH team on a tour through the Lafayette HFH headquarters, which currently houses the bicycles that will be used in Cover Indiana. The main problem that we are tasked to solve is that there is no easy way to transport the bicycles from the second floor down to the ground. Currently, the only way that the bikes can be moved is from people carrying the bicycles up and down the stairs, which not only uses intensive manual labor, but also has a risk of injury from falling.

Additionally, the project can also be used to develop other solutions that can transport other materials across floors. We are also looking into developing a similar solution for raising and lowering insulation cubes in the Pole Barn, which faces a similar problem as the cubes are heavy and dangerous to carry on stairs. However, at this point, Habitat (our project partner) has asked us to focus on the lift in the Habitat headquarters first over the Pole Barn lift.

One of the problems at we will face is that not only do we have to have a design that works, but also it will have to work around existing obstacles, like these ladders in the Pole Barn.

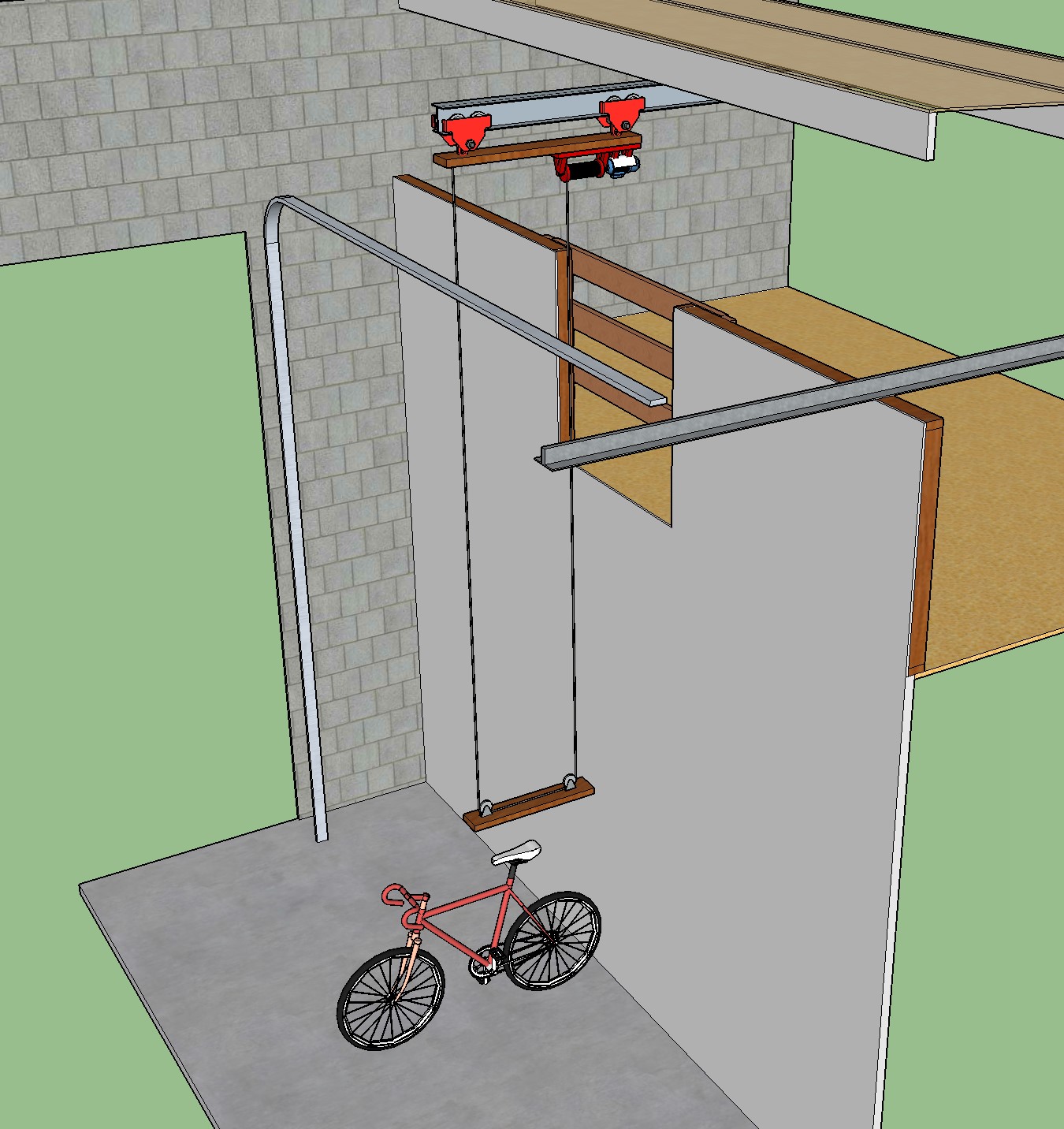

At the end of the fall semeseter, we are currently finishing up the conceptual design phase for the lift system in the Habitat Headquarters. We have made three different design matrices for load support, work mechanisms, and attachment methods. Through these, we have picked our potential design of a sliding I-beam trolley that will be powered by an electric winch. The bike will be attached with a locking snap hook. A preliminary sketch of what this might look like is shown below.

We are aiming to finish this project and deliver it to Habitat for Humanity by the end of the spring semester.

App Team

What is it?

The Data Storage Team is working with Habitat for Humanity Lafayette affiliate to develop a system to allow them to track their inventory effectively. Their equipment ranges from simple tools, like hammers and screwdrivers, to more important and expensive tools, nail guns and jackhammers. Currently, HFH has no formal inventory list they use to track their items, thus leading to wasted time trying to find tools needed on one of the build sites. Furthermore, knowledge of tools leaving the HFH location is limited and hard to keep track of currently.

What will it look like?

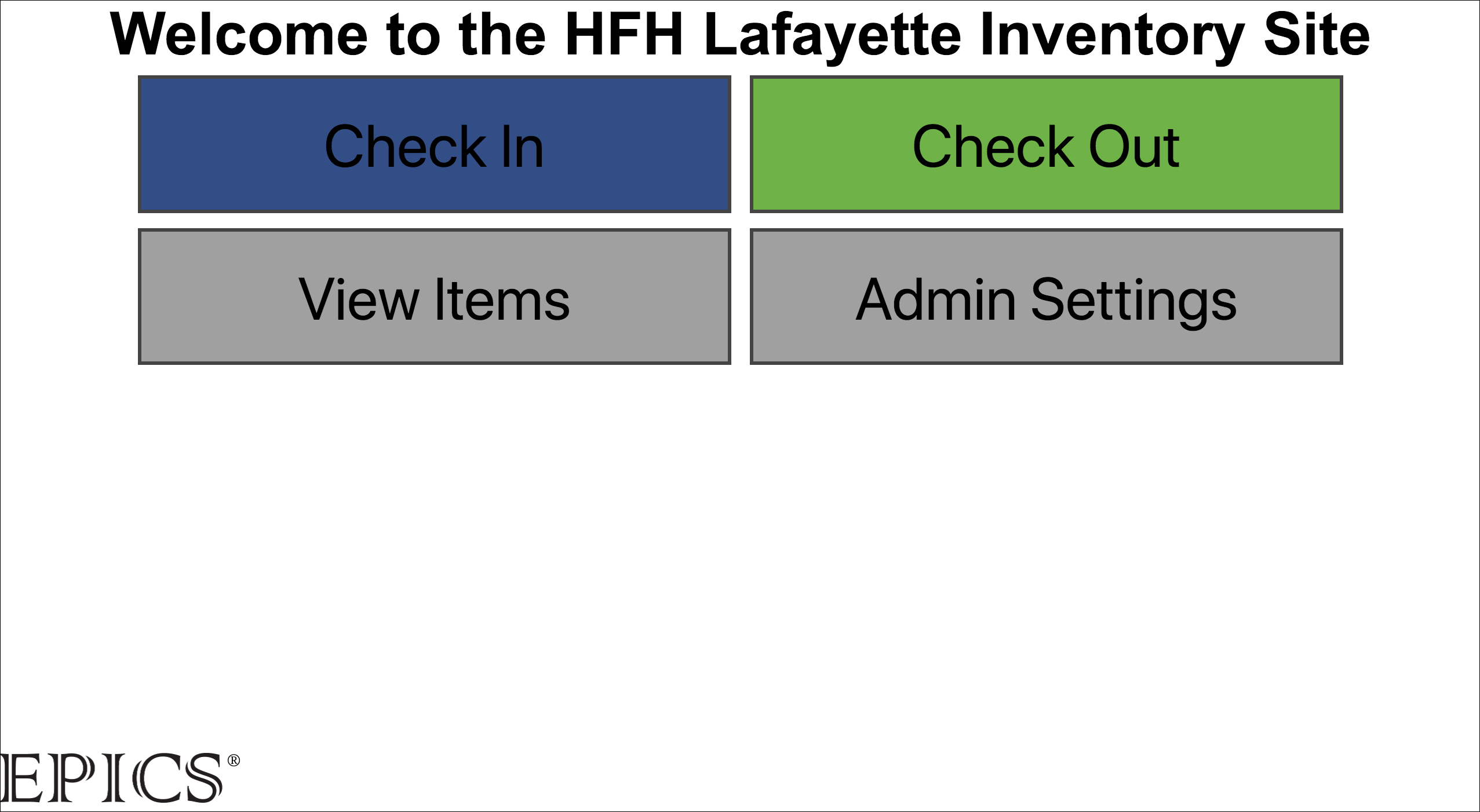

In the Spring Semester of 2018 the App team made significant progress in creating an easy to use web application for the Habitat for Humanity staff and volunteers. Although there is still much to do, the App team has created a minimum viable product. The photo below shows the preliminary design of what the team thought the app would be in future semesters. Although this has not been created, a mobile app is still on the horizon for the Habitat for Humanity EPICs team.

At the end of Fall 2017 semseter, the App team had narrowed down how the application would be programmed to four possible ways. There were three framework options with Web2py, Angular, and Bubble, which all require minimal coding experience. The last option is to just hard-code the app. Hard coding takes more coding expertise, but is higher functioning in almost every way. In the Spring of 2018, the App team explored all of the options. After careful deliberation, it was decided that hard coding the app would be the best solution, and that angular would suffice for coding a mobile application, but that would have to come at a later time. Below the first protoype of the app can be seen.

Loft Team

During the initial visit to the Habitat headquarters on September 8, 2016, Sue Hunter led the students upstairs through an unorganized loft space of the Habitat headquarters. The team noticed a slew of safety issues present in the loft and took on the task of creating a safe, easily traversable space. The team broke the overall safety issue into 5 main hazards. These hazards were: Framing Futures equipment, railings, hole in the wall, low beams, and signs.

Framing Futures

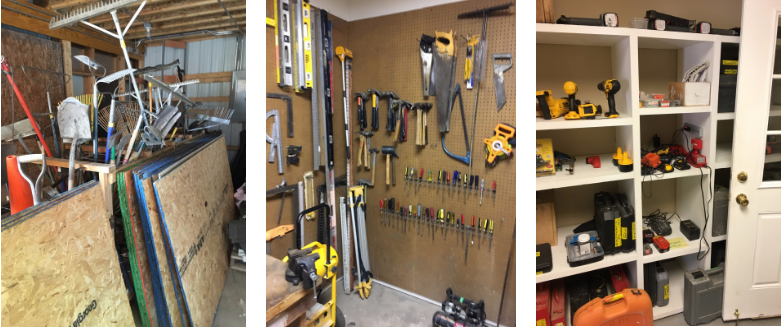

Framing futures is an event that teaches youth some craftsmanship skills such as basic carpentry. The Framing Futures program uses hands on experience to teach these skills and as such has a dedicated collection of tools for the program. This collection was kept in the loft. The tools (pictured below left) were kept in a pile on the floor of the loft. The Loft Team deemed this as a tripping hazard and created a solution to move the equipment off of the floor into a shelf. The team, in fall 2016, built a shelf (pictured below right) and implemented it into the loft. The shelf improved safety and increase traversability in the loft as the Framing Futures tools were now placed on the shelf and out of the walkway.

Railings

The team assessed the railings already present in the loft through multiple visits. The teams concluded that the railings were not stable enough to hold the OSHA specified weights in multiple places. The team also concluded that the railings were not in accordance with OSHA regulations on the height of railings as they were far too short. The railings were 2 feet 8 inches, 10 inches below the OSHA standard. The team has created the design shown below, in which the railing will be heightened by installing a series of gas pipe, shown in blue. With approval from Habitat for Humanity Staff members for the design shown below the team will begin purchasing materials and constructing the solution.

Hole in Wall

The team, in the first visit to Habitat for Humanity's Lafayette affiliate office noticed an issue with the railings that needed to be addressed quickly. There was a large hole in the railing that was quite obviously a hazard as anyone in the loft could easily fall through the opening. The team suggested to the HFH staff, at the mid-semester design review, that a simple solution would be to just fill the hole with a proper railing. At this time the HFH staff informed the team that the hole in the wall had a function; to move items too large to fit through the stairs to be lifted in to the loft. The team still deemed the hole unsafe and began work on a new solution.

The team worked with HFH staff directly to create a valid solution as the staff had many specific requests for the solution. The staff and the team decided on a solution that maximized floor space in the loft and simplicity of design that still made the hole safe but still usable. The team, in accordance with the HFH staff input, decided to fill the hole in the wall with a set of two wooden 2x4s that fill the hole but are easily removable as they are held in place by stake holders.

The HFH staff raised concerns at the final design review presentation that the solution implemented had some flaws. Mainly the 2x4s had a tendency to fall out of the stake holders in which they are placed. The HFH staff present gave many ideas on what possible solutions could be which included: lengthening the 2x4s, adding an additional 2x4 for more stability if an employee happens to fall into the solution and implementing a device of sorts in order to stabilize and hold the 2x4s in place. The team has taken this input and is working on creating a solution to the problem at hand.

Low Beams

The team noticed almost immediately the presence of a number of beams in the loft that were in the way of a person walking through the loft. The beams were low hanging and presented considerable risk of injury if a person should run in to one of them. These beams are made of metal and had little to no padding or indication that they were there. The team went through many possibilities for a solution and ultimately decided, through the use of the EPICS design process including a design matrix, to install pool noodles on the beams to decrease the risk of injury in the event that a collision occurs between the beam and a persons body, specifically the head. Also through the same process the team determined a caution sign would increase safety as the users of the loft would be made aware of the risk of the beams. The pool noodles were ordered in early winter 2016, however, due to difficulties in the shipping process the pool noodles did not arrive until late January 2017. The team quickly worked to install the noodles to increase safety in the loft. The installation took place on January 26, 2017.

The sign was crafted and laminated by the Loft Team, then installed on February 11, 2017.

Signs

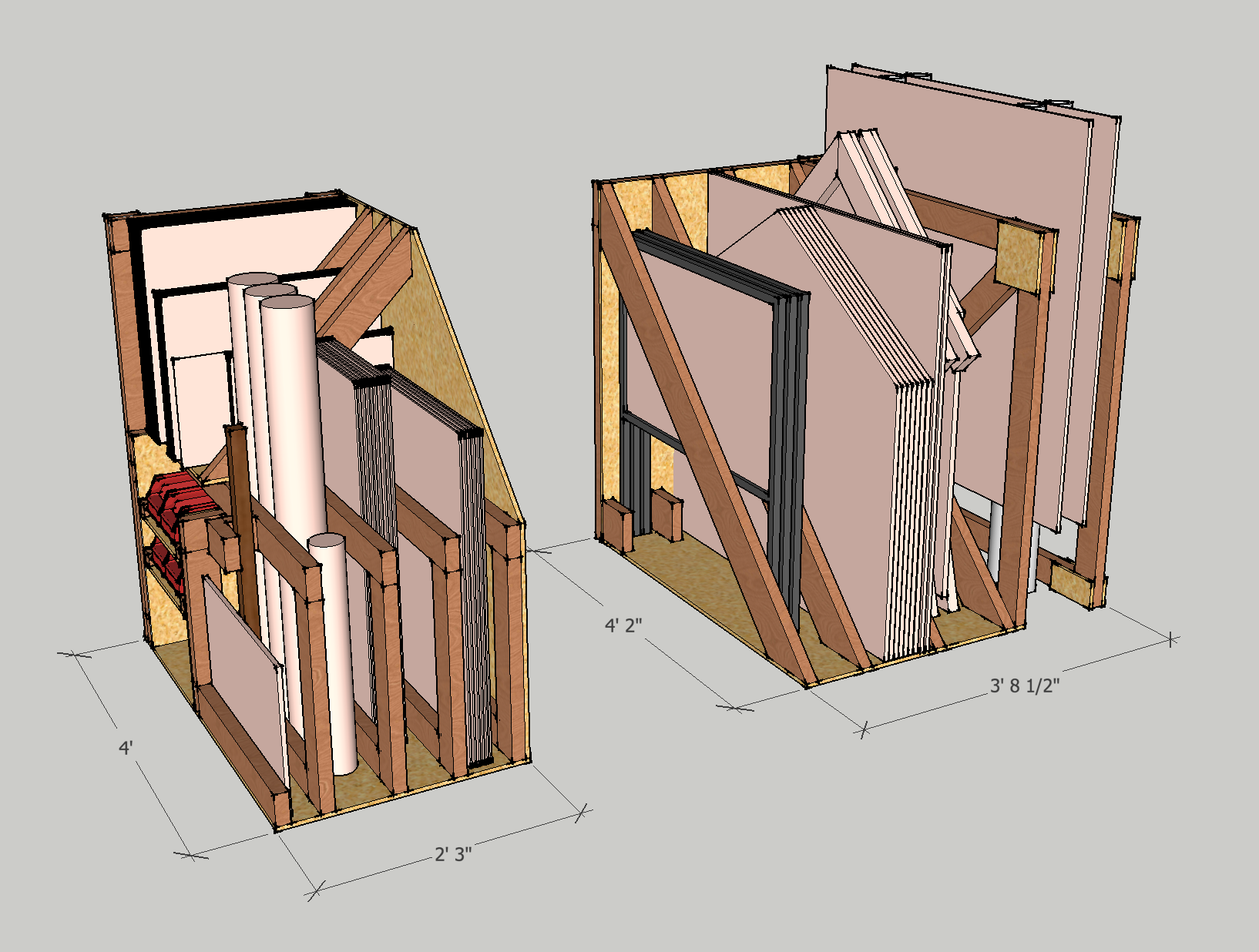

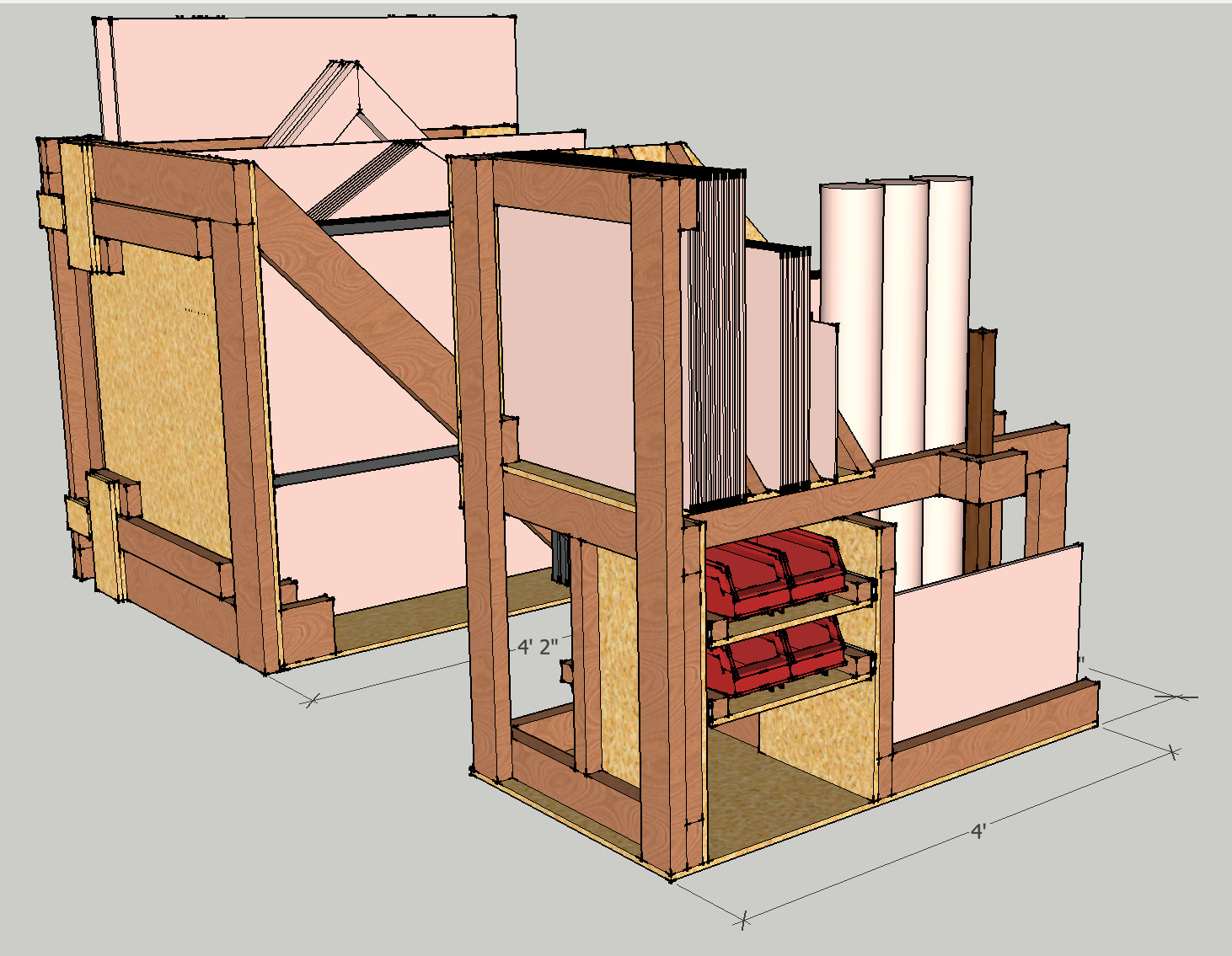

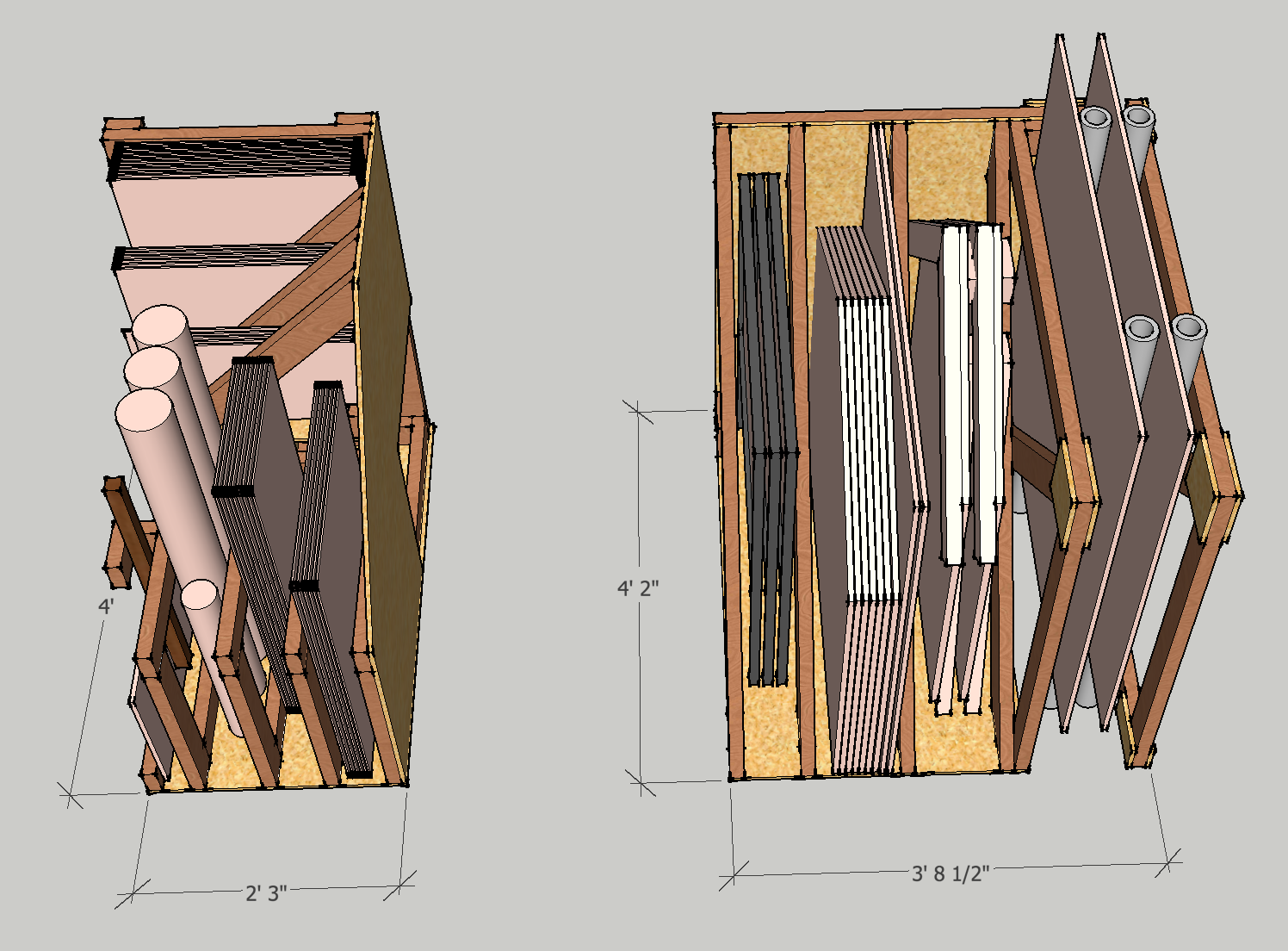

The HFH team, while on the first site visit, was given explicit instructions from HFH full time volunteer Sue Hunter, to design an implement a solution for the issue of sign storage. At that time the team took note of the lack of organization of the signs. the signs were stacked in piles in various locations throughout the loft and some signs were even being stored in a different HFH Lafayette building. The team decided to build a unit in order to consolidate all of the signs and create an easier and safer interaction with the signs. The team worked extensively with HFH employees and volunteers to design and redesign multiple solutions. The storage system grew in size over time to accommodate not only the amount of signs but also the size of the signs with some reaching upwards of 8 feet tall. While the sign storage system is still in the detailed design phase of the EPICS design process the team hopes to, in compliance with the HFH staff and volunteers complete the design, construct the solution, and implement the system by the end of the spring 2017 semester.

Delivered Projects (Spring 2017)

Railing Solution

Low Beams Solution

Sign Sorter Module 1

Sign Sorter Module 2